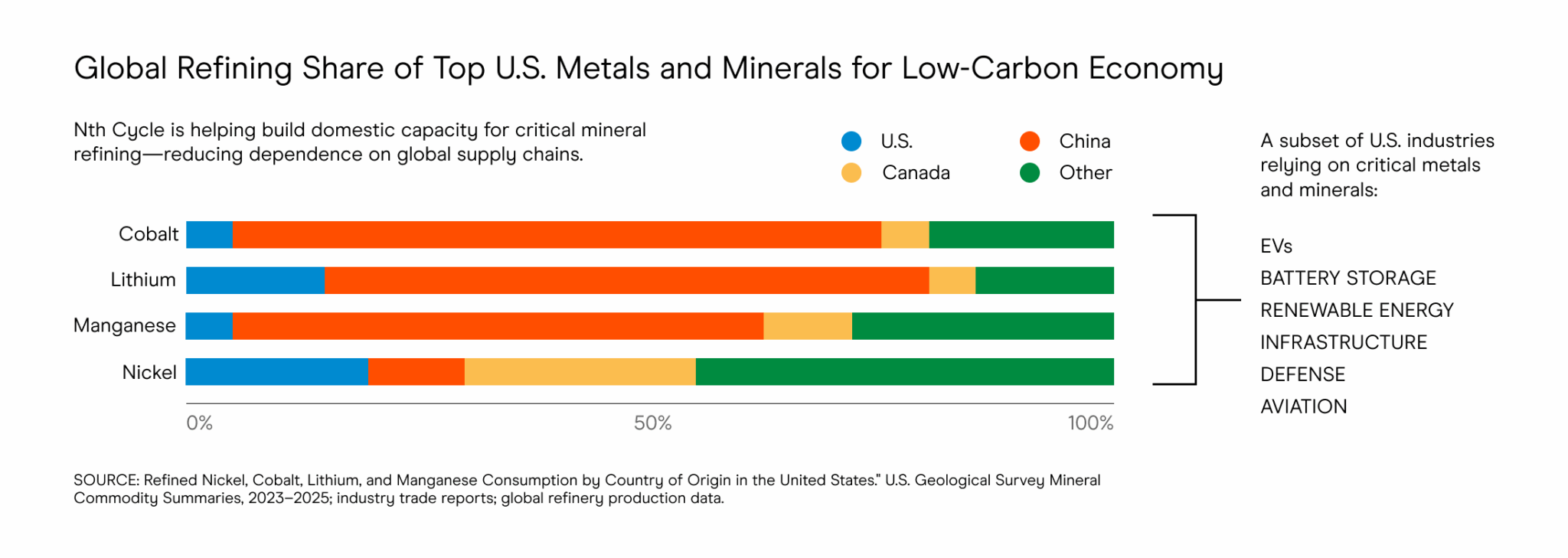

The world’s access to critical minerals is increasingly concentrated in just a few countries—in particular China, the Democratic Republic of Congo, and Indonesia – even as access to minerals becomes increasingly important across energy, computing, infrastructure, and other parts of the economy. Current projections suggest that by 2030, the U.S. will only have a market share of approximately 1.6% in critical minerals such as copper, cobalt, lithium, nickel, and other rare earth metals. However, the growing supply of scrap metal and end-of-life materials—like old batteries and recycled electronics—present an opportunity to extract and refine minerals closer to home.

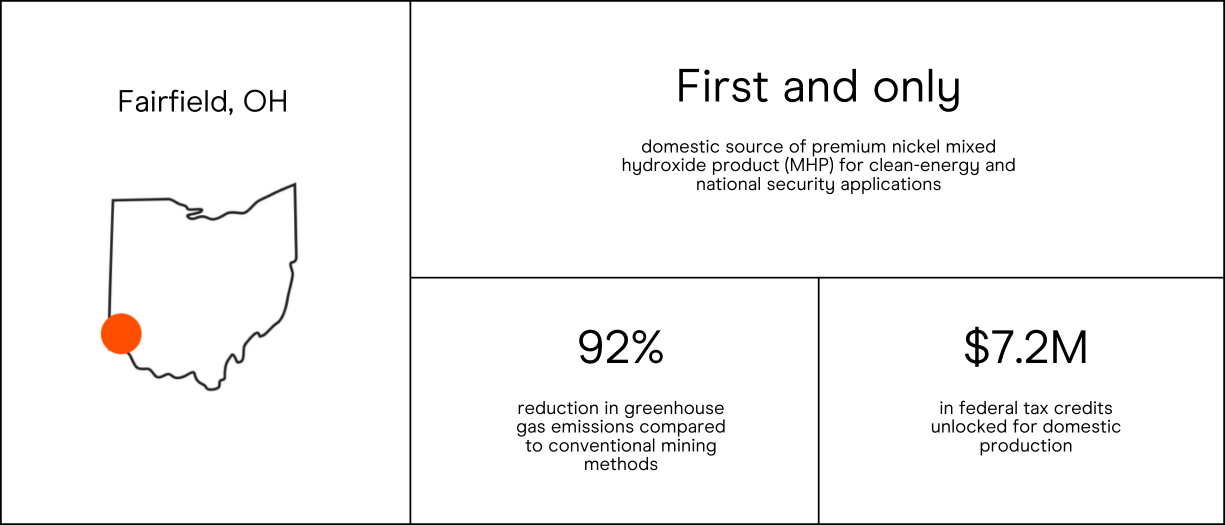

This is where Nth Cycle comes in. In the fall of 2024, they became the first company in the United States to produce premium nickel cobalt mixed hydroxide product (MHP) from scrap. In less than a year, with support from mission driven investors like Elemental, they installed and operationalized their revolutionary “Oyster” system in Fairfield, Ohio to recover critical minerals that can be utilized in building new batteries, solar panels, semiconductors, and military systems. Nth Cycle’s unique model is creating quality manufacturing jobs in communities transitioning from traditional industries.

Now operational, Nth Cycle’s Ohio facility represents a historic breakthrough with national significance:

The Opportunity: bringing critical minerals to the U.S.

85% of the world’s critical metals are refined in China. Without a sufficient domestic refining capability, the U.S. will remain reliant on overseas supply chains with economic, environmental, and geopolitical implications.

Demand for nickel, cobalt, lithium, manganese and copper is growing exponentially, leading to broader and deeper mining—while batteries and other e-waste are crowding our landfills, rich with the same minerals, but without a clean, profitable way of converting them for end-use. Until now.

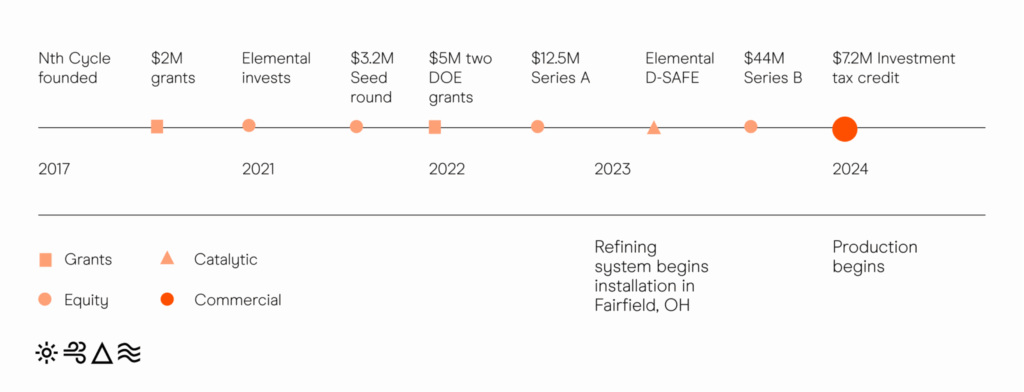

When we first met Megan O’Connor, Nth Cycle’s co-founder and CEO, in 2021, she was leading a four-person team, developing an initial pilot, and closing a $3.2M seed round. Her vision was to revolutionize critical mineral production through a new “electro-extraction” technology that uses electricity—instead of fossil fuels—to recover the full spectrum of high-purity minerals from old batteries, scrap metal, and mined ore. Nth Cycle’s technology reduces greenhouse gas (GHG) emissions by 44% compared to traditional recycling, and 92% compared to laterite mining.

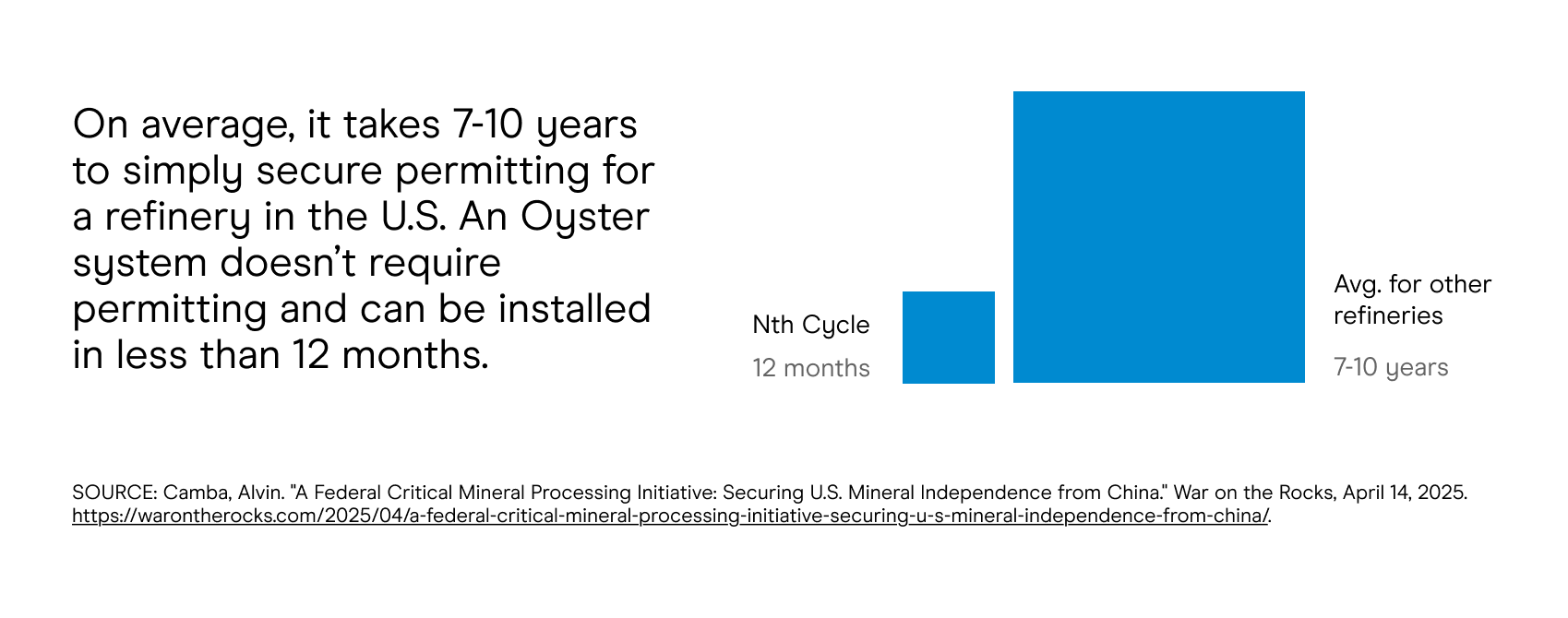

The Oyster system is modular, allowing Nth Cycle to co-locate their technology with existing recycling, manufacturing, and mining facilities. This eliminates the need to transport materials across the country for processing, and avoids the years of approvals and billions of dollars spent on building a stand-alone refining plant. It also creates an opportunity for Nth Cycle to partner with existing, often family-owned, businesses to bolster the local economy and generate wealth directly in the communities where it’s installed.

“Without critical minerals, the country can’t function. And being dependent on other nations for those resources can’t continue. By onshoring critical metal refining, Nth Cycle is addressing the longest standing, most vulnerable and valuable gap in the supply chain. It’s hard to overstate how significant that is.” – Megan O’Connor, Nth Cycle CEO and Co-Founder

Elemental’s Investment: catalytic capital and strategic coaching to de-risk and scale

In 2021, Elemental made its first investment into Nth Cycle, recognizing the novel technology as a breakthrough solution for bringing mineral production closer to home.

Elemental’s initial investment and coaching strengthened both fundraising and sales strategies, helping to accelerate their timeline by 6-8 months, expand their customer pipeline from 1 to 8 potential partners, grow their workforce from 8 to 16 employees, and ultimately secure a successful $12.5M Series A in 2022. This momentum positioned Nth Cycle to scale their refining system from pilot to commercial capacity at the existing facility in Fairfield.

In October 2023, we conducted a follow-on investment and deepened our support during this critical scale-up phase with a Development-SAFE (D-SAFE) investment to tackle critical pre-development needs—including building an apprenticeship framework with Ohio-based educational institutions, developing a local engagement plan with family-owned scrap facilities, joining the Butler Tech Workforce Hub to connect with skilled workers in Ohio’s energy sector, and conducting a well-attended ribbon-cutting event with bipartisan policy stakeholders.

Nth Cycle scaled quickly from there. Following our strategic investment, Nth Cycle secured a $7.2M manufacturing investment tax credit (48C) for the Ohio deployment and announced a $44M Series B round.

In addition to helping preserve and strengthen existing local businesses, the Fairfield facility has created 8-10 new jobs, sourced directly from the local community—including chemical engineers, technicians, quality control, quality insurance, and engineering leads. It now serves as a model for Nth Cycle’s expansion in the Midwest and beyond.

“As with any early-stage venture, successes are often driven by the community around you. Elemental offers a robust, talented, and driven network of changemakers who help companies like ours expand outside of our own circle of influencers, which has been a tremendous help to Nth Cycle’s growth.” – Megan O’Connor, CEO and co-founder

Scaling Up: investing in new production facilities across the country

Close to one third of all greenhouse gas (GHG) emissions are produced by the industrial sector, yet the sector has only received seven percent of climate investment. By localizing critical minerals refining, Nth Cycle will dramatically reduce emissions generated by status quo refining processes, which depend on cross-continental shipping and transit—making it imperative that we invest more in this sector to continue to innovate and reduce emissions.

As for what’s next, Nth Cycle is planning for five deployments across the U.S. and Europe in the next three years, utilizing a combination of equity and debt, to scale their processing capacity by 10x. As part of this, they will also expand their list of recovered materials to include copper and rare earth metals for magnet technology.

Central to their scaling strategy is building local trust and engagement in each new location. Nth Cycle plans to onboard Community Managers tailored to each project’s local context, who will work with advisory councils, Chambers of Commerce, and workforce development offices to increase visibility around the company’s mission and technology’s positive community impact. This grassroots approach is designed to streamline the deployment process and ensure each facility becomes a valued partner from day one.

Nth Cycle’s technology validation and business momentum has generated substantial public and private sector interest. Manufacturers are seeking more sustainable and domestically sourced materials, while the current administration has prioritized establishing an on-shore critical metal supply chain with a specific focus on refining. The company’s approach offers a compelling solution that addresses both supply chain security and environmental concerns in a single technology.